Product

Certifications

Jinjie has passed a lot of well-known certifications for the product quality, managment, services, etc.

Including: ISO 9001, ISO 14001, CE, 3A, New High-tech Enterprise, many Patents, ect.

Jinjie people will...View More

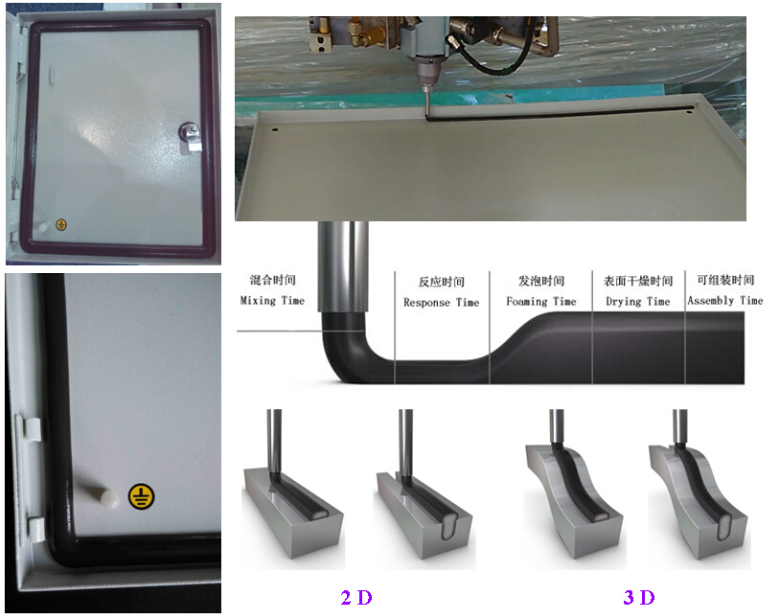

Form-in-Place Advantages

Form-in-Place Advantages

Less waste and greater cost savings:

EMI and RF shielding materials can be expensive. There is significantly less material waste with FIP, and our dispensed form-in-place gaskets offer significant material cost savings when compared to conductive die cut gaskets. Since the form-in-place gaskets are dispensed directly on the work piece by the CNC robots, the material cost savings can be dramatic.

Shorter lead times:

The automated FIP process speeds up production by eliminating the need for manual assembly of die cut or molded gaskets.

Many material combinations:

With dozens of material to choose from, Form in Place gaskets are ideal solutions for countless applications. Conductive silicone rubber is available with a number of fillers, such as Ag/Al, Ag/Cu, Ag/glass, Ni/C, Ni/Al and Carbon black.

Excellent adhesion:

FIP materials adhere to a range of substrates, including conductive and painted plastics, metals and metal alloys, and metallized surfaces. The RTV (Room temperature vulcanization) or UV (Ultraviolet) cured gasket bead naturally adheres directly to the work piece.

Greater precision and tighter tolerance:

Form-in-place gaskets can be dispensed on intricate work pieces, including those with changes in elevation. Our CNC robots were developed to dispense precise form-in-place gasket beads on even the most complex work pieces. Gaskets requiring thin profiles, our robots easily dispense intricate shapes and/or changes in the Z-axis or elevation.

13889624989

13889624989 sales01@fipfgmachine.com

sales01@fipfgmachine.com