Product

Certifications

Jinjie has passed a lot of well-known certifications for the product quality, managment, services, etc.

Including: ISO 9001, ISO 14001, CE, 3A, New High-tech Enterprise, many Patents, ect.

Jinjie people will...View More

Aluminium brigde cut machine

Hiqh quality aluminum profiles processing machine

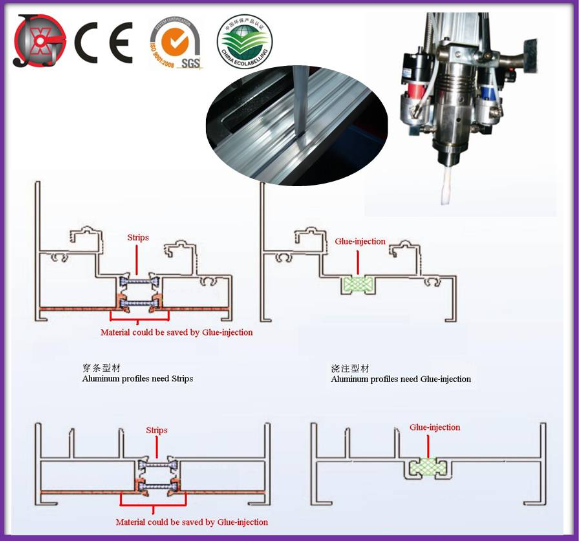

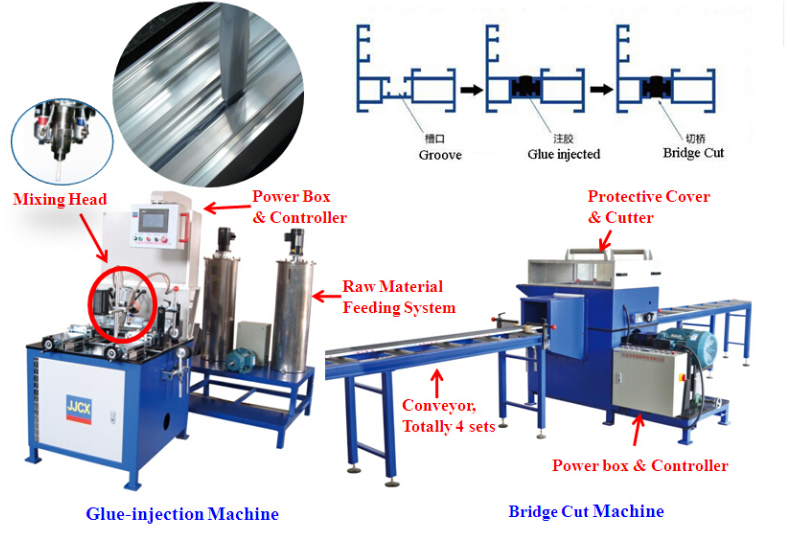

This equipment has two main functions: inject the raw materialinto the groove of aluminum profiles, when the material cured, cut off the bridge; Then, the aluminum profiles obtain the functions such as heat insulation, etc. (The raw material is thermal insulation material, the glue)

Comparing with old aluminum profiles, the new one has wonderful heat insulation function, and much much stronger, especially could save a lot of cost.

Constructions and Main Parts:

| Construction | Dimensions | |

| 1 | Material Feeding System | |

| 2 | Glue-injection machine | 1200*1400*2100H mm |

| 3 | 4 Conveyors | 400*6000mm |

| 4 | Bridge cutting machine | 1750*1110*1550H mm |

| 5 | Dust collector |

| Glue-injection machine | Bridge cutting machine | ||||

| Dosing | Viking metering pump | Blade |

Dia 300mm, 350mm, or 400mm THK: 3-4mm |

||

| Feeding | Ingersolland plunger pump | Driving | Electric motor driving synchronous pulley | ||

| Mixing head | Patent design, alloy steel | Security | Special protective cover, if the cover is open, or the small door for changing blade is open, the power would be cut off. | ||

| Control | CNC, control raw material temprature, mixing, feeding automatically. | ||||

| Material barrel | 70L, with material level controller, mixing settings, temprature controller, feeding system. | ||||

| Cleaning | By dichloromethane, stainless steel material container | ||||

| Driving | Electric motor driving synchronous pulley | ||||

Specifications:

| Glue-injection machine | Bridge cutting machine | Note | |||

| Cavity Size | 220W*150H mm | 220W*150H mm | can be adjusted for custom-made | ||

| Power | 380V, 6KW | 380V, 9KW | Can follow the national standard | ||

| Running Speed | 0~60m/min | 0-60m/min | |||

Jinjie is a professional supplier and manufacturer of solutions for polyurethane automatic equipment system and other sealing systems, and integrated with design, R&D, production, marketing, and after-sales services. The company is located in Dalian, one of the most important port cities in the north of China.

We have excellent R&D team: A group of professionals majored in chemical engineering, machinery, automatic control, and etc. We are versatile and powerful in machining: One specialized factory for machining, where custom-made equipment can be produced quickly. The core technology of product is top-level: it is from German, and the components are from world-renowned suppliers. Our service system is perfect: huge distribution network, professional technology support, excellent after-sales service group and so on.

Main product: 2/3-components FIPFG sealing solutions equipment, PU Foam Sealing Equipment, Microscale Sealing System, Cabinet Sealing Machine, Lightings Sealing Gasket Machine, Automatic Car Sealing System, Silicon Sealing equipment, Dispensing Machine, Spreading Equipment, Gluing Machine, Thermally Insulating Aluminum Profiles Gluing & Cutting Equipment, Custom-made Machineries etc.

We Believe: Innovation Leads The Future, Cooperation Creates A Better Future.

13889624989

13889624989 sales01@fipfgmachine.com

sales01@fipfgmachine.com